The Heart of Automobile

Maliha Mumtaz Mim, ME (2021-22)

The word engine derives from Old French engine, from the Latin ingenium–the root of the word ingenious which is the heart of an automobile. A machine for converting any of various forms of energy into mechanical force and motion is generally defined as engine. When discussing cars, the word "engine" usually refers to an internal combustion engine. An internal combustion engine is a kind of heat engine that produces power by burning fuel inside a combustion chamber. The car is then propelled forward by converting this power into mechanical motion.

Any reciprocating internal combustion engine operates on this basic principle: when a small quantity of gasoline or another high-energy-density fuel is ignited in a small, enclosed space, a massive amount of energy is released in the form of expanding gas.

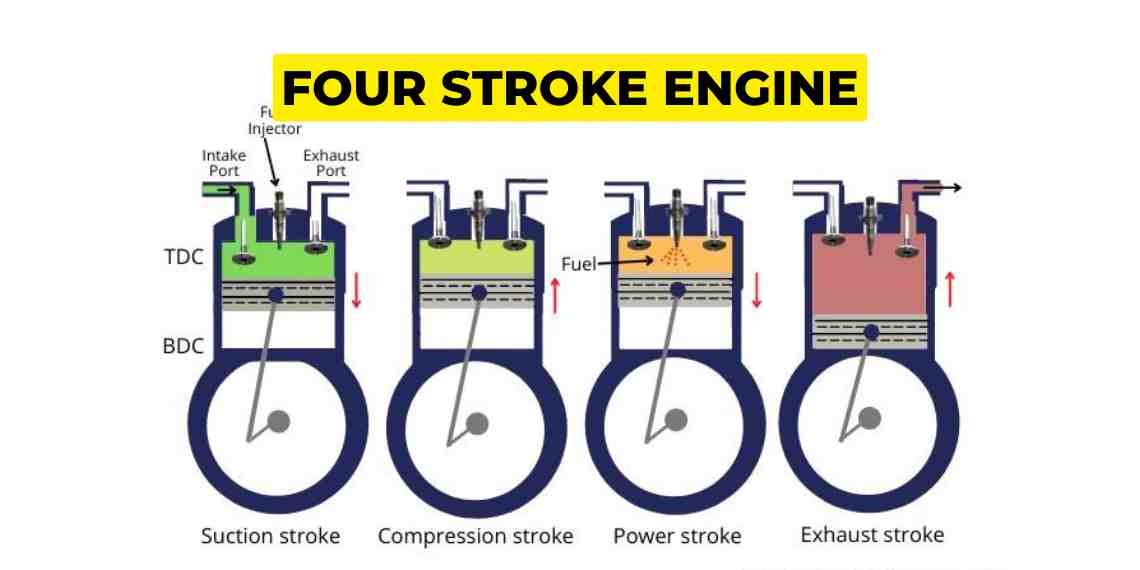

That energy can be put to creative uses. For instance, the heart of an automobile engine can be created if a cycle is developed that permits the detonation of explosions like these hundreds of times per minute and can be utilized to generate energy. A four-stroke combustion cycle is used in almost all gasoline-powered cars to turn fuel into motion. The Otto cycle, named after Nikolaus Otto, is another name for the four-stroke method. It was developed in 1867. The animation provides examples of the four strokes.

The four strokes are –

Intake stroke

Compression stroke

Expansion stroke

Exhaust stroke.

The piston is connected to the crankshaft by a connecting rod. As the crankshaft revolves, it has the effect of "resetting the cannon." Here's what happens as the engine goes through its cycle:

The piston starts at the top, the intake valve opens, and the piston moves down to let the engine take in a cylinder full of air and gasoline. This is the intake stroke. Only the tiniest drop of gasoline needs to be mixed into the air for this to work. (Part 1 of the animation)

Then the piston moves back up to compress this fuel/air mixture. Compression makes the explosion more powerful. (Part 2 of the animation)

When the piston reaches the top of its stroke, the spark plug emits a spark to ignite the gasoline. The gasoline charge in the cylinder explodes, driving the piston down. (Part 3 of the animation)

Once the piston hits the bottom of its stroke, the exhaust valve opens, and the exhaust leaves the cylinder to go out the tailpipe. (Part 4 of the animation)

Now the engine is ready for the next cycle, so its intakes another charge of air and gas. In an engine, the linear motion of the pistons is converted into rotational motion by the crankshaft. The rotational motion is nice because we plan to turn (rotate) the car's wheels with it anyway. Now let's look at all the parts that work together to make this happen, starting with the cylinders.

Basic Parts

The typical internal combustion engine has around 200 parts that need to be maintained and possibly replaced if they wear out. The core of the engine is the cylinder, with the piston moving up and down inside the cylinder. Single cylinder engines are typical of most lawn mowers, but usually cars have more than one cylinder (four, six and eight cylinders are common). In a multi-cylinder engine, the cylinders usually are arranged in one of three ways: inline, V or flat (also known as horizontally opposed or boxer), as shown in the figures to the left.

So that inline four we mentioned at the beginning is an engine with four cylinders arranged in a line. Different configurations have different advantages and disadvantages in terms of smoothness, manufacturing cost and shape characteristics. These advantages and disadvantages make them more suitable for certain vehicles. Let’s look some main parts of automobile.

Cylinder

Spark plug

Connecting rod

Crankshaft

Cylinder

An integral part of an internal combustion engine is the engine cylinder, a cylindrical chamber where fuel and air are burned. The engine's cylinder bank is made up of several cylinders that are normally placed inside the engine block in a row or a V shape. An engine can have one, six, or eight cylinders, though four, six, and eight-cylinder variants are frequently used in automobile applications. The principal elements and characteristics of an engine cylinder are as follows:

Cylinder wall: The outer surface of the cylinder, which forms the boundary of the combustion chamber. It is usually made of cast iron or aluminum and provides structural support to the engine block.

Cylinder bore: The inner diameter of the cylinder, defining the size of the combustion chamber. The size of the bore influences the engine's displacement and performance characteristics.

Piston: A cylindrical component that moves up and down inside the cylinder. The piston is connected to the crankshaft by a connecting rod. During the engine's operation, the piston undergoes reciprocating motion, which is converted into rotational motion by the crankshaft.

Piston ring: These are circular rings fitted around the piston. They help create a seal between the piston and the cylinder wall, preventing the escape of combustion gases and ensuring efficient energy transfer.

Combustion chamber: The space enclosed by the cylinder, piston, and cylinder head where the air-fuel mixture is ignited. The design of the combustion chamber influences factors like compression ratio and combustion efficiency.

Engine problems

Engines can experience a variety of problems due to factors such as wear and tear, inadequate maintenance, fuel issues, or manufacturing defects. Here are some common engine problems:

Overheating

Poor fuel efficiency

Noisy operation

Smoke from exhaust.

Oil leaks.

Excessive vibration etc.

Engine Valve Train and Ignition

The engine valve train and ignition system are critical components in an internal combustion engine, playing essential roles in the combustion process that powers the vehicle. Let’s discuss each system separately:

Engine Valve Train

The valve train is responsible for controlling the opening and closing of the engine’s intake and exhaust valves. It consists of various components that work together to synchronize the valve movements with the engine’s piston movements. The main components of the valve train include:

Camshaft: This is a rotating shaft with lobes or cams that control the movement of the valves. The camshaft is driven by the engine's crankshaft through a timing belt or chain.

Valves: There are intake and exhaust valves in each cylinder. The intake valve allows the air-fuel mixture to enter the cylinder, while the exhaust valve allows the exhaust gases to exit.

Valve Lifters: These are components that transfer the motion from the camshaft to the valves. There are different types of lifters, such as hydraulic lifters and mechanical lifters.

Pushrods and Rocker Arms: In engines with an overhead valve (OHV) design, pushrods transfer the motion from the lifters to the rocker arms, which then actuate the valves.

Springs and Retainers: Valve springs are used to keep the valves closed and ensure proper valve seating. Retainers hold the springs in place.

Timing Belt or Chain: This component connects the crankshaft and camshaft, ensuring proper synchronization of valve and piston movements.

Ignition System

The ignition system is responsible for generating a high-voltage spark to ignite the air-fuel mixture in the engine's cylinders. The key components of the ignition system include:

Spark Plugs: These are devices that produce an electric spark to ignite the compressed air-fuel mixture in the combustion chamber.

Ignition Coil: The ignition coil transforms the low-voltage electrical power from the battery into high-voltage power required for the spark plugs.

Distributor (or Ignition Module): In traditional ignition systems, the distributor distributes the high-voltage current to each spark plug in the correct firing order.

Ignition Timing: The timing of the spark is crucial for optimal engine performance. It is controlled by the ignition system to ensure that the spark occurs at the right moment in the engine's four-stroke cycle.

Electronic Ignition: Modern vehicles often use electronic ignition systems that may not have a distributor. Instead, they use sensors and an Engine Control Unit (ECU) to precisely control ignition timing.

Engine Lubrication, Fuel, Exhaust and Electrical Systems

To ensure that the right amount of air and fuel can enter the cylinders, the engine's fuel system pumps gas from the gas tank and blends it with air. Modern cars typically use one of two methods for fuel delivery: direct fuel injection or port fuel injection.

A fuel-injected engine injects the exact amount of fuel into each cylinder one at a time, either directly into the cylinder (direct fuel injection) or just above the intake valve (port fuel injection). Carburetion was a method used in older cars to combine gasoline and air as the air entered the engine.

Oil has a significant role as well. To ensure that the engine runs smoothly, the lubrication system ensures that oil reaches all of the working parts. The pistons (to enable them to glide readily in their cylinders) and any bearings that permit the crankshaft and camshafts to operate freely are the two primary components that require oil.

The muffler and the exhaust pipe are parts of the exhaust system. You would hear thousands of tiny explosions shooting out of your exhaust if you didn't have a muffler. A muffler muffles sound wave.

Modern cars have a catalytic converter, a number of sensors and actuators, and a computer to monitor and regulate everything when it comes to pollution control. To burn up any leftover gasoline and certain other substances in the exhaust, for instance, the catalytic converter employs oxygen and a catalyst. The catalyst needs oxygen to function, thus an oxygen sensor in the exhaust stream checks and modifies the amount as needed.

The engine is one of the more essential concepts in machinery and machinery working. A machine can’t be adequately called until it has an engine. An engine is used in three-wheelers, passenger cars, trucks, etc. The size of the motor depends on the use of that engine. Engines like petrol and diesel engines are also available with enhancements to work in extreme conditions.

Moreover, its maintenance is essential to keep the car engine’s life. Some car owners ignore the proper care of the machine, and this practice will make your car burn out even earlier than expected. When used, the engine changes its status, e.g., installed new oil or filter. If a certain period does not change engine fluids, it will cause the engine to die early because of a lack of lubrication and cooling when it is running. Do you like the blog post? Please share your thoughts with us.